自動焊接設(shè)備的注意事項以及分類

來源:http://www.fx361.com.cn/ 發(fā)布時間:2023-06-03 瀏覽次數(shù):0

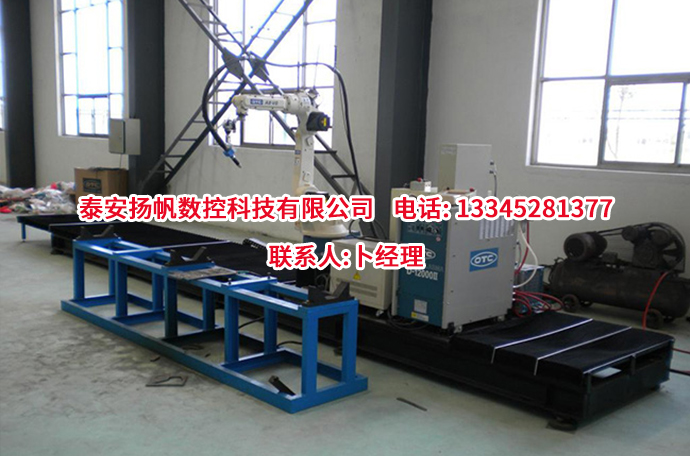

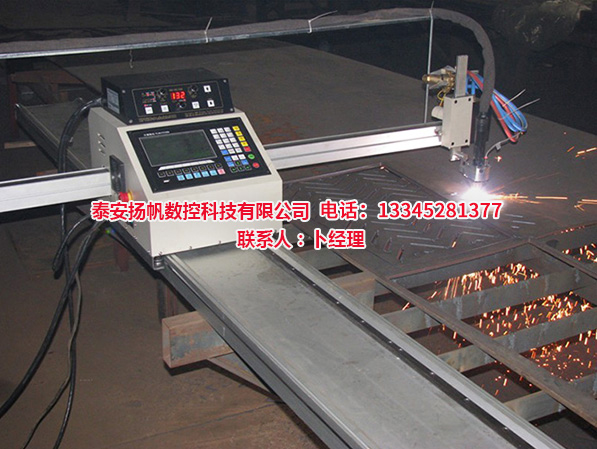

自動焊接設(shè)備在當(dāng)下的適用范圍非常的廣,自動焊接設(shè)備受歡迎的原因在于自動焊接設(shè)備相比較傳統(tǒng)焊接方法來看,焊接精度更加準(zhǔn)確,而且隨著近幾年自動焊的應(yīng)用,越來越多的人開始關(guān)注自動焊接設(shè)備的發(fā)展,下面,就讓我們一起來深入了解一下山東自動焊接設(shè)備的注意事項以及分類吧。

The application range of automatic welding equipment is very wide at present. The reason why automatic welding equipment is popular is that compared to traditional welding methods, automatic welding equipment has more accurate welding accuracy. Moreover, with the application of automatic welding in recent years, more and more people are paying attention to the development of automatic welding equipment. Now, let's take a deeper look at the precautions and classifications of automatic welding equipment in Shandong.

一、自動焊接設(shè)備的注意事項:

1、 Precautions for automatic welding equipment:

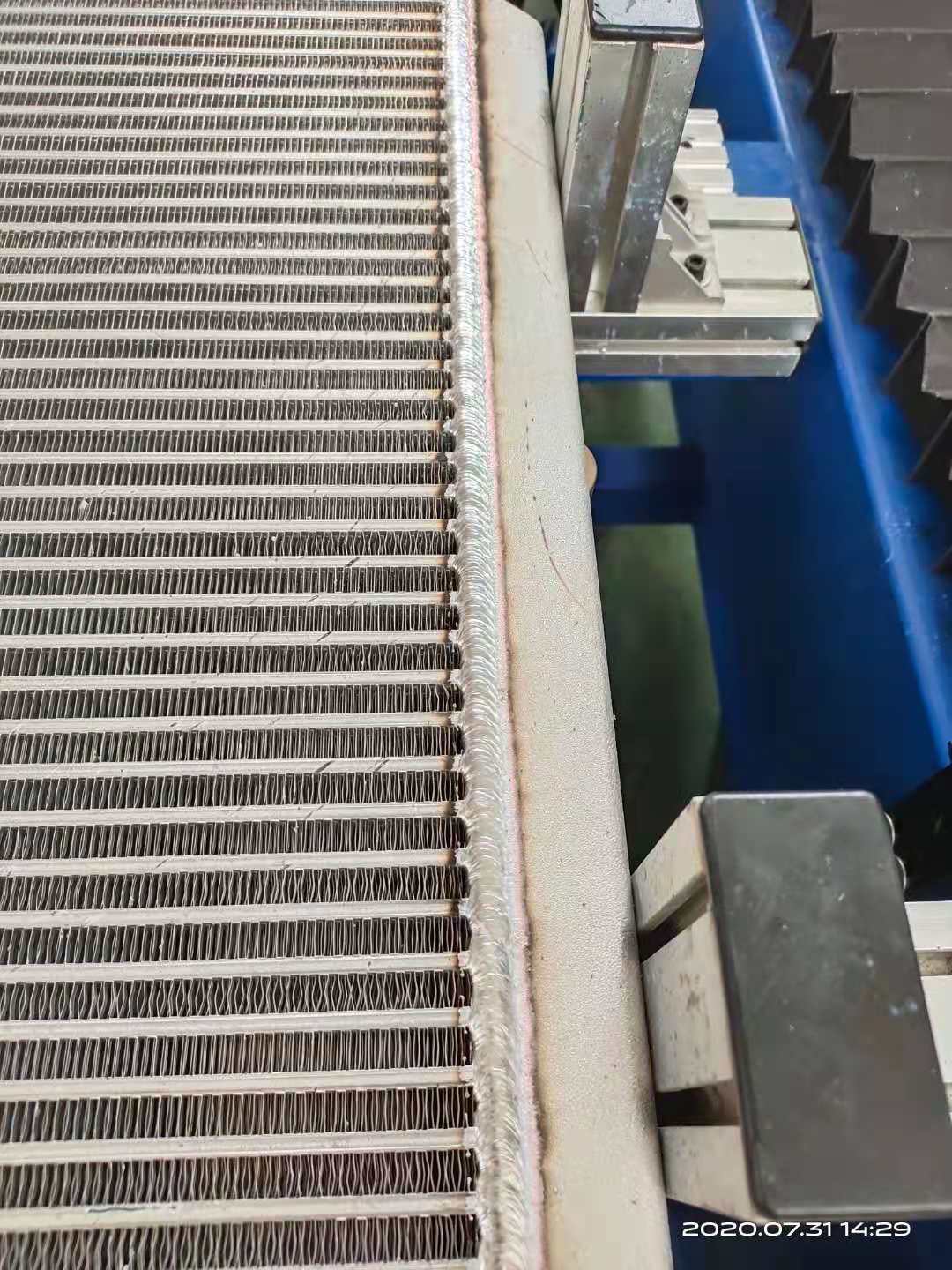

1、靈活多樣的焊接方法同時支持點焊和電阻焊接(拉焊)。自動焊設(shè)備的所有工藝參數(shù)可由客戶自行設(shè)定,以適應(yīng)各種困難的焊接操作和微焊接工藝。所有焊接參數(shù)可隨焊點坐標(biāo)程序一起讀取和保存,從而完成焊接操作的靈活性。

1. Flexible and diverse welding methods support both spot welding and resistance welding (pull welding). All process parameters of the automatic welding equipment can be set by the customer to adapt to various difficult welding operations and micro welding processes. All welding parameters can be read and saved together with the welding point coordinate program, thereby achieving flexibility in welding operations.

2、烙鐵組件可以任意角度和方向調(diào)節(jié),控制烙鐵組件的R軸,360度自由旋轉(zhuǎn)。焊接次數(shù)、預(yù)熱時間和焊接時間可以根據(jù)不同的焊盤和元器件任意設(shè)定,從而完成一個板上多個焊點的復(fù)雜焊接過程,焊接操作多樣化。

2. The soldering iron component can be adjusted at any angle and direction, controlling the R-axis of the soldering iron component to rotate 360 degrees freely. The welding frequency, preheating time, and welding time can be arbitrarily set according to different pads and components, thus completing the complex welding process of multiple solder joints on a board, with diversified welding operations.

3、四軸/五軸聯(lián)動機械手和自動焊設(shè)備均采用伺服驅(qū)動和的運動控制算法,有效提高了移動端焊頭的定位精度和重復(fù)精度,完成了三維空間任意焊點的準(zhǔn)確定位。

3. The four/five axis linkage manipulator and automatic welding equipment both adopt servo drive and advanced motion control algorithms, effectively improving the positioning accuracy and repetitive accuracy of the moving end welding head, and completing the accurate positioning of any welding point in three-dimensional space.

二、根據(jù)程度,自動焊接設(shè)備可分為以下三類:

2、 According to the degree of activation, automatic welding equipment can be divided into the following three categories:

1、剛性自動焊設(shè)備:剛性自動焊設(shè)備也可稱為初級自動焊設(shè)備,大多數(shù)都是根據(jù)開環(huán)控制原理設(shè)計的。雖然整個焊接過程都是由焊接設(shè)備主動完成的,但閉環(huán)反饋系統(tǒng)不能應(yīng)用于焊接過程中焊接參數(shù)的波動,可能出現(xiàn)的偏差也不能隨意修正。

1. Rigid automatic welding equipment: Rigid automatic welding equipment, also known as primary automatic welding equipment, is mostly designed based on the principle of open loop control. Although the entire welding process is actively completed by the welding equipment, the closed-loop feedback system cannot be applied to fluctuations in welding parameters during the welding process, and possible deviations cannot be arbitrarily corrected.

2、自控式自動焊設(shè)備:自控式焊接設(shè)備是一種具有高度主動性的焊接設(shè)備。配有傳感器和電子檢測電路,主動引導(dǎo)和跟蹤焊接軌跡,并由閉環(huán)對主要焊接參數(shù)進行反饋控制,整個焊接過程將根據(jù)預(yù)設(shè)的程序和工藝參數(shù)主動完成。

2. Automatic control welding equipment: Automatic control welding equipment is a highly proactive welding equipment. Equipped with sensors and electronic detection circuits, it actively guides and tracks the welding trajectory, and the main welding parameters are feedback controlled by a closed-loop system. The entire welding process will be actively completed according to the preset program and process parameters.

3、智能自動焊設(shè)備:智能自動焊設(shè)備采用視覺傳感器、觸覺傳感器、聽覺傳感器和激光掃描儀等各種傳感元件,依靠計算機軟件系統(tǒng)、數(shù)據(jù)庫和系統(tǒng),具有識別、判別、實時檢測、操作、主動編程、焊接參數(shù)存儲和主動生成焊接記錄文件的功能。

3. Intelligent automatic welding equipment: Intelligent automatic welding equipment adopts various sensing components such as visual sensors, tactile sensors, auditory sensors, and laser scanners, relying on computer software systems, databases, and expert systems. It has the functions of recognition, discrimination, real-time detection, operation, active programming, welding parameter storage, and active generation of welding record files.

自動焊接設(shè)備注意事項以及分類的相關(guān)內(nèi)容分享,通過以上的自動焊接設(shè)備的介紹,相信大家對自動焊接設(shè)備都有了一定的了解,希望以上的介紹可以幫助到大家。更多相關(guān)事項就來我們網(wǎng)站http://www.fx361.com.cn咨詢吧!

Sharing the relevant content on precautions and classification of automatic welding equipment. Through the above introduction of automatic welding equipment, I believe everyone has a certain understanding of automatic welding equipment. I hope the above introduction can help everyone. For more related matters, come to our website http://www.fx361.com.cn Consult!